From Layout to Delivery: Grasping the Art of T-Shirt Screen Printing

The trip from design to delivery in t-shirt screen printing encompasses a series of essential phases that demand attention to information and calculated planning. It begins with comprehending the subtleties of your target market, followed by the selection of appropriate materials and the prep work of artwork that satisfies high criteria. As the process unravels, obstacles in high quality control and logistics can arise, potentially influencing the final result. Exploring these complexities exposes not just the complexities of screen printing but additionally the essential techniques that can boost a brand name's standing in an open market.

Understanding T-Shirt Screen Printing

Comprehending T-Shirt screen printing includes identifying a functional and extensively made use of method for transferring styles onto fabric. This technique utilizes a mesh and a pattern screen to apply ink onto various textile materials, generally cotton and polyester blends. The procedure starts with the creation of a screen that includes the wanted layout, which is then carefully straightened on the textile.

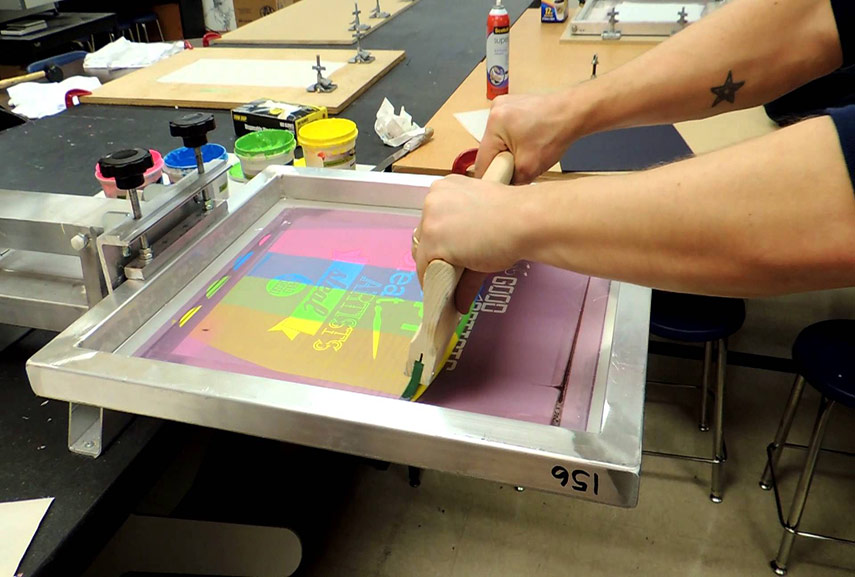

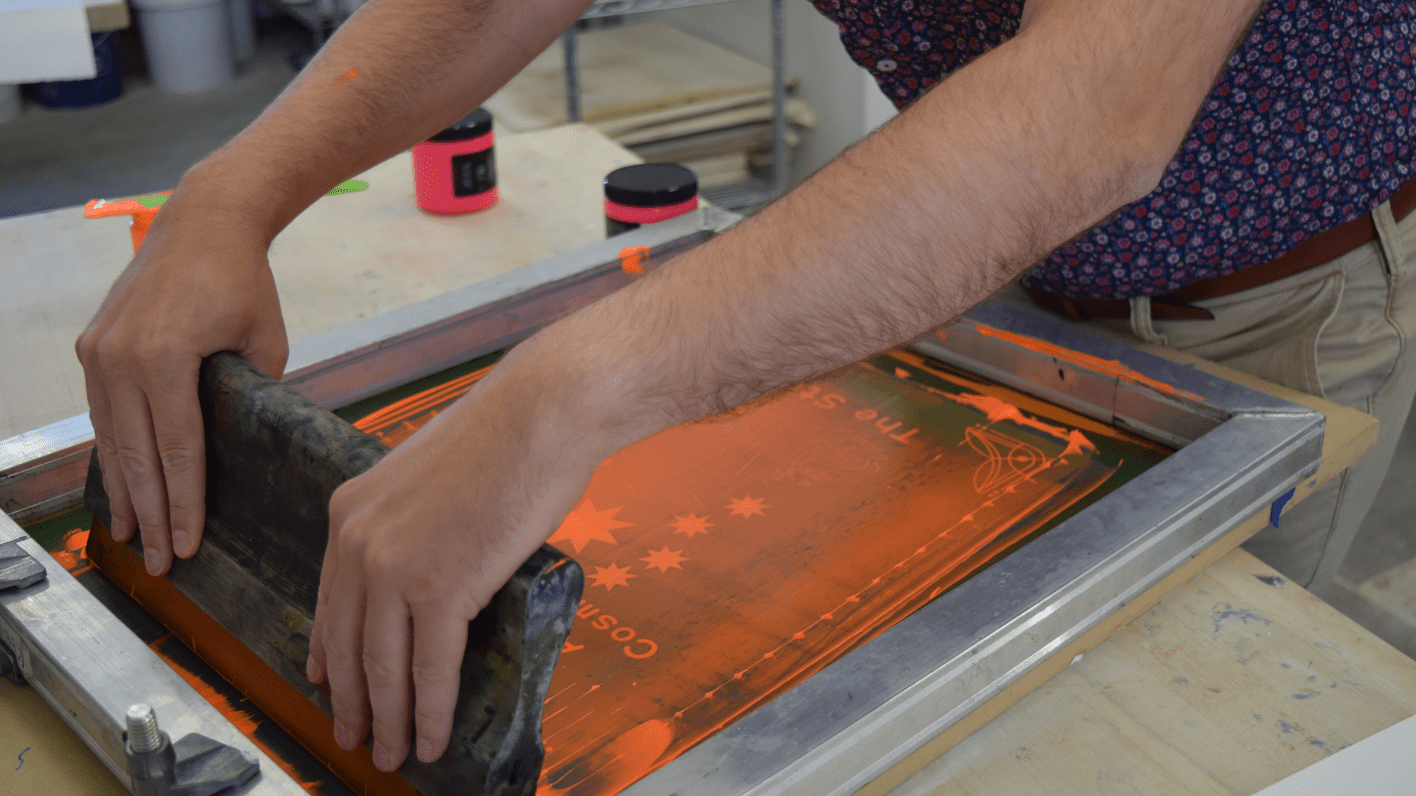

Ink is pressed through the screen's open areas utilizing a squeegee, permitting accurate application of shade. This approach is preferred for its capability to produce lively, durable prints that stand up well to cleaning and wear. Furthermore, screen printing is qualified of suiting both basic and complex layouts, making it a favored option for custom apparel, marketing items, and also creative works.

Screen printing uses scalability, making it ideal for both tiny batch orders and massive manufacturings. While preliminary setup expenses may be greater compared to other printing approaches, the effectiveness and sturdiness of screen printing usually justify the investment. On the whole, understanding the principles of T-shirt screen printing is important for anyone aiming to take part in this popular type of textile decor, whether for individual projects or business ventures.

Conceiving Your Style

Conceiving your design is a crucial action in the Tees screen printing procedure, as it establishes the structure for the entire project. This phase includes creating concepts that reverberate with your target market while making sure that the design aligns with the brand name's identity and message. It is vital to begin by exploring styles, color pattern, and graphics that mirror the designated visual.

Mapping out preliminary concepts can be beneficial, enabling a graph of ideas prior to settling the layout (Business Branding Services). Think about using typography, imagery, and design in a manner that catches focus and interacts properly. On top of that, it is crucial to anticipate the printing method that will certainly be utilized, as this can affect style intricacy and shade options

Participating in brainstorming sessions with group members or looking for feedback from prospective clients can also boost the conceptualization process, supplying varied point of views that refine the style. Ultimately, a well-thought-out style not just boosts the aesthetic allure of the T-shirt however also promotes a link with the target market, driving interest and prospective sales. For that reason, committing time to conceptualize your design can result in a successful screen printing outcome.

Selecting the Right Products

When picking the right materials for Tee shirts screen printing, it is necessary to take into consideration the textile's weight, texture, and composition, as these aspects considerably impact the last product's quality and really feel. Cotton is a popular choice as a result of its breathability, softness, and capability to take in ink properly, making it perfect for dynamic prints - T-Shirt Printing. Blends, such as cotton-polyester, deal durability and crease resistance, but may influence ink adherence, requiring careful consideration of printing techniques

The weight of the material, normally gauged in grams per square meter (GSM), influences the drape and total feeling of the T-shirt. Much heavier fabrics might offer an extra superior appearance, while lighter choices fit for sportswear. Structure additionally plays a duty; smoother fabrics tend to generate sharper prints, while distinctive surfaces can develop one-of-a-kind aesthetic effects.

In addition, consider the environmental effect of materials. Organic cotton and recycled polyester are getting appeal amongst eco-conscious customers. Ultimately, choosing the appropriate products involves stabilizing aesthetic appeal, functionality, and sustainability, making sure that the Tees not only looks wonderful yet also satisfies the expectations of your target market.

Preparing Art Work for Printing

Preparing artwork for T-shirt screen printing calls for cautious interest to detail to guarantee that the last print properly mirrors the desired design. The very first step is to develop a high-resolution digital file, ideally in vector style, as this enables scalability without loss of quality. Common software application utilized for this objective includes Adobe Illustrator and CorelDRAW.

Think about the dimensions of the print location and preserve proper margins to prevent layout cutoff. It's additionally smart to include enrollment marks for positioning during the printing procedure. Demand a proof from the printer to visualize the final product before mass manufacturing. This step is essential for recognizing any kind of potential issues, ensuring that the printed Tees meets the preferred high quality and design requirements. Appropriate preparation of artwork significantly affects the total success of the screen printing job.

Grasping the Printing Process

Next off, picking the right ink is very important. Various ink kinds, such as plastisol or water-based, deal numerous finishes and longevity. Understanding the textile make-up of the T-shirt likewise assists in choosing compatible inks.

Regulating the squeegee pressure and angle is critical when it comes to the real printing. Constant stress will certainly produce even ink distribution, while the angle affects the flow and protection. Additionally, adjusting the rate of the printing machine can affect the ink's healing procedure, which is basic for ensuring durability.

Top Quality Control and Finishing

After the printing procedure is total, executing effective top quality control steps comes to be important to validate that each Tee shirts fulfills the desired criteria. Quality control entails a methodical technique to checking each garment for issues, confirming that the print quality, shade accuracy, and textile stability align with the specifications established during the layout stage.

The primary step in high quality control is a detailed visual evaluation. This involves checking for typical issues such as misalignment, ink smudges, or fading. Any kind of Tee shirts that does not fulfill the high quality standards must be attended to without delay, either via reprinting or repair service.

In enhancement to aesthetic checks, it is necessary to carry out clean examinations on an example of published tee shirts to assess the sturdiness of the inks and the general longevity of the layout. These examinations assist confirm that the print will keep its vibrancy and stability after multiple washes, an important variable for customer fulfillment.

Ending up touches, such as thread cutting and the application of treatment tags, likewise play a significant function in quality assurance. By concentrating on these facets, businesses can improve the overall discussion of their items, eventually bring about an extra satisfying customer experience.

Packaging and Delivery Solutions

Effective packaging and delivery remedies are vital elements of the Tees screen printing process, as they assure that garments come to their location in pristine problem. Correct product packaging not just shields the published designs however additionally enhances the unboxing experience for consumers, strengthening brand identification and professionalism.

To attain ideal product packaging, take into consideration utilizing green materials that straighten with sustainability patterns, such as recyclable poly bags or eco-friendly boxes. Each T-shirt should be nicely folded and positioned in safety wrapping to protect against creasing and possible damage during transit. Consisting of a top quality insert or treatment directions can further individualize the experience, cultivating consumer commitment.

Selecting a trusted delivery partner is crucial when it comes to delivery. Assess alternatives based upon speed, expense, and tracking abilities. Providing numerous shipping methods can accommodate various consumer needs, from common to expedited shipping.

Frequently Asked Concerns

What Are the Common Blunders Beginners Make in Screen Printing?

Usual errors novices make in screen printing consist of improper screen preparation, inadequate ink mixing, incorrect direct exposure times, inadequate curing, and disregarding to examine prints. These mistakes can bring about bad top quality and unsatisfactory lead to last items.

Just How Can I Stop Ink From Bleeding Throughout Printing?

To avoid ink bleeding during printing, assurance proper screen tension, usage proper solution thickness, choose the appropriate ink consistency, maintain excellent treating temperatures, and prevent overloading the screen with excessive ink throughout application.

What Sorts of Inks Are Finest for Various Fabrics?

Selecting inks based upon material kind is crucial. Water-based inks are ideal for cotton, supplying gentleness. Plastisol inks fit artificial textiles, providing resilience (Abilene T-Shirt Screen Printing Company). Release inks properly mix with natural fibers, guaranteeing vivid shades without compromising material stability

Exactly how Do I Pick the Right Screen Mesh Count?

Picking the ideal screen mesh count relies on the preferred print detail and ink type. Greater mesh matters produce better details, while lower matters help with thicker inks. Evaluate fabric kind and design complexity for excellent outcomes.

Can I Use Screen Printing for Little Set Orders?

Yes, screen printing can be effectively used for small batch orders. Business Branding Services Abilene. This technique permits for top quality results and detailed layouts, making it a viable option for personalized garments, advertising products, or restricted edition runs

Understanding T-Shirt screen printing entails identifying a flexible and extensively used method for moving styles onto fabric. While initial configuration costs might be greater contrasted to other printing methods, the performance and sturdiness of screen printing frequently warrant the financial investment. see post Preparing art work for Tees screen printing needs cautious attention to information to guarantee that the last print properly mirrors the intended style. Grasping the printing process is essential for achieving high-quality results in Tees screen printing. Typical errors novices make in screen printing consist of inappropriate screen preparation, insufficient ink blending, incorrect direct exposure times, not enough treating, and ignoring to examine prints.